Corrosion is a significant problem in industries where disinfection processes are frequent and of critical importance.

According to Sarah Koehler—a commercial manager at France’s Axcentive Group, producers of the popular biocide Halamid®—using too many peroxygen-based disinfectants can corrode, tarnish and degrade pumps, pipes, cages, grills and other pieces of equipment that are essential for modern fish farms and poultry barns.

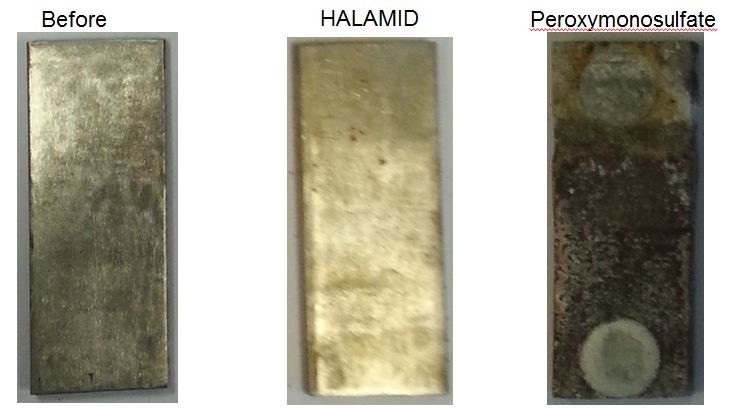

As such, it should come as no surprise that many disinfecting solutions have undergone corrosion tests. These include Halamid®, which recently went head-to-head against a peroxymonosulfate-based product, using ASTM norm 1384 as the basis for the experiment.

This approach enabled researchers to test the corrosiveness of liquid (in this case, a 1% solution of Halamid®) by checking various substrates at the same time. To ensure accurate results, the two disinfectant solutions were changed daily. During the test, six different materials—copper, brass, steel, stainless steel, aluminium, and PP—underwent the same number of cycles in the disinfectant solution in an open, aerated refluxing vessel.

The results of the experiment speak for themselves. Weight loss measurements provided quantitative proof that Halamid® is less corrosive to metals than the peroxymonosulfate-based product that was tested.

These findings confirm that—when compared to substrates—the neutral pH of Halamid® and its mild oxidative properties have a limited impact on metals used in modern poultry- and aquaculture.

While it’s true that all disinfectants all have different benefits and drawbacks, Axcentive is optimistic that these results will help both aquaculturists and poultry farmers make an informed decision when choosing which disinfectant to use in environments where corrosion remains a pervasive problem.

For more information about Halamid®, please visit www.axcentive.com. You can also email info@axcentive.com or call our sales office at +33 442 694 090.